Vmc1165 Vertical Machining Center

Product Overview This series vertical machining center adopts the moving structure of cross sliding table and sliding guide,which is mainly applied in processing of middle and small scalecomplicated parts.Apply the computeraided engineering(CAE)system to finish theoptimized structure design and enha......

Send Inquiry

Product Description

Product Overview

Machine Characteristics

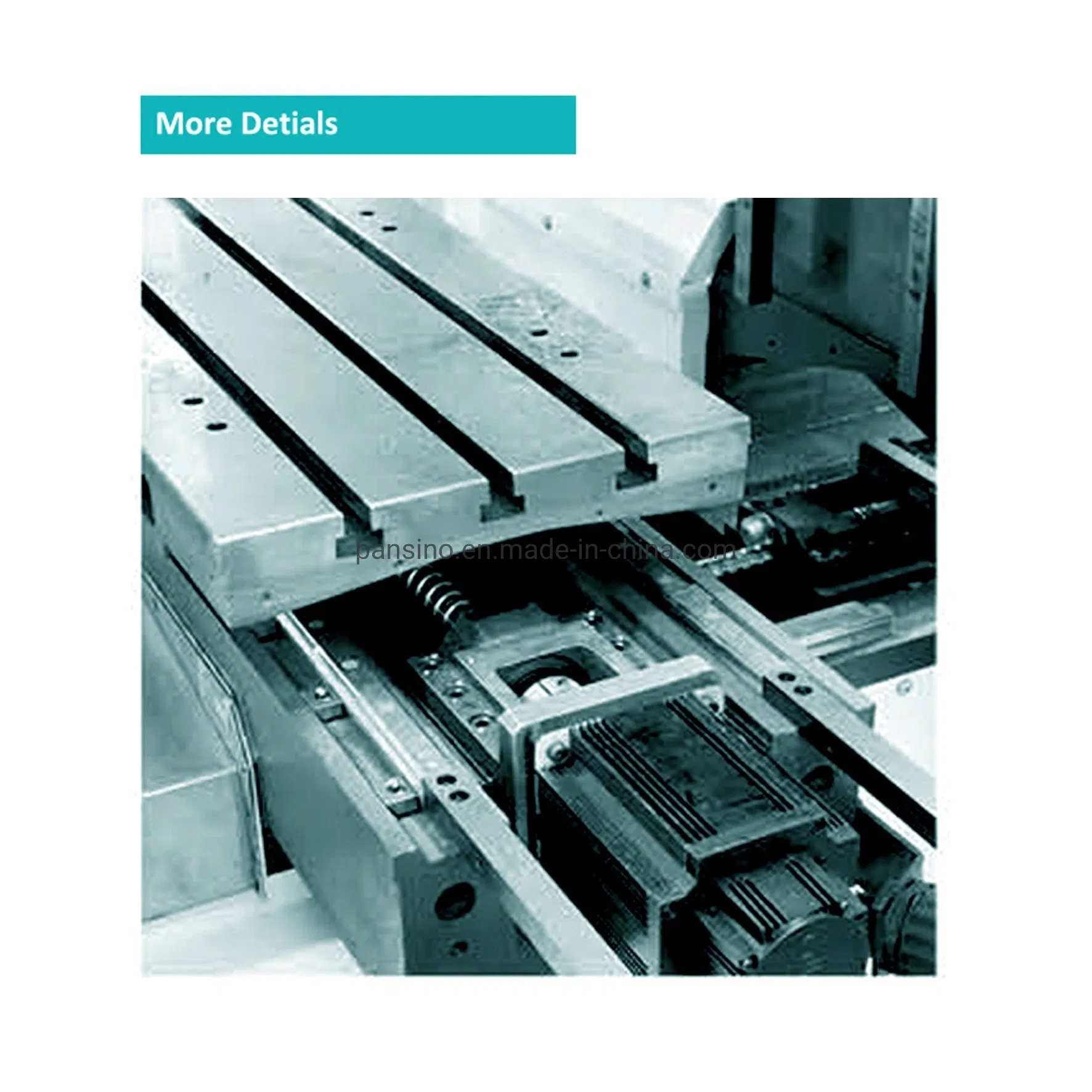

1.The major machine components apply finest gray cast iron which are of good shock resistance. All the casts have been done with aging treatment twice, in order to eliminate the internal residual stresses. So that, our machine can work with high rigidity and good shock resistance for heavy cutting and intermittent cutting.

This series vertical machining center adopts the moving structure of cross sliding table and sliding guide,which is mainly applied in processing of middle and small scale

complicated parts.Apply the computeraided engineering(CAE)system to finish the

optimized structure design and enhance the reliability of machine tool,and the finite element method(FEM)to take the scientific analysis and optimization of design structure,

which can guarantee the rigidity and stability of the whole machine structure.It can finish allkinds of processing,such as milling,drilling,expanding,boring,tapping and profile milling

at one time of clamping.It is suitable for the parts processing with high precision,

multipe procedure and complicated shape.It is the key facility in industries of general machinery,mold,aviation,energy and traffic.

multipe procedure and complicated shape.It is the key facility in industries of general machinery,mold,aviation,energy and traffic.

Machine Characteristics

1.The major machine components apply finest gray cast iron which are of good shock resistance. All the casts have been done with aging treatment twice, in order to eliminate the internal residual stresses. So that, our machine can work with high rigidity and good shock resistance for heavy cutting and intermittent cutting.

2.Key components are designed with CAD software, in this way, the optimal structure can be analyzed out by computer, which ensure the good intensity,rigidity and thermal stability.

3.The joint face of components are manually polished well, which guarantees the effective contacting area.

Machine Parameters(FANUC 0I MF, OTHER CNC CONTROLS OPTIONAL)

Machine Parameters(FANUC 0I MF, OTHER CNC CONTROLS OPTIONAL)

| CODE | ITEM | DETAILS | ||||||

| 1 | WORKTABLE(WIDTH×LENGTH) | mm | 650*1300 | |||||

| 2 | T SLOTS | mm | 5-18 | |||||

| 3 | DISTANCE BETWEEN T SLOTS | mm | 125 | |||||

| 4 | MAX.LOAD BEARING OF WORKTABLE | kg | 1000 | |||||

| TRAVEL | ||||||||

| 5 | X AXIS | mm | 1100 | |||||

| 6 | Y AXIS | mm | 650 | |||||

| 7 | Z AXIS | mm | 665 | |||||

| 8 | DISTANCE FROM COLUM TO SPINDLE CENTER | mm | 700 | |||||

| 9 | DISTANCE FROM TABLE TOP SURFACE TO SPINDLE NOSE | mm | 150-815 | |||||

| SPINDLE | ||||||||

| 10 | SPINDLE HOLE TAPER | BT40 | ||||||

| 11 | SPINDLE SPEED RANGE | r/min | 20-8000 | |||||

| 12 | MAIN MOTOR MODEL | βiI 12/ 10000 | ||||||

| 13 | SERVO MAIN MOTOR RATED POWER | kw | 11 | |||||

| 14 | SERVO MAIN MOTOR 30MINS POWER | kw | 15 | |||||

| 15 | SERVO MAIN MOTOR RATED OUTPUT TORQUE | Nm | 52.5 | |||||

| 16 | SPINDLE PART DYNAMIC BALANCE TYPE | G1 | ||||||

| 17 | SPINDLE ACCURACY | SPINDLE FACE RUNOUT::0.005mm | ||||||

| SPINDLE RADIAL RUNOUT :NEAR-END 0.007mm | ||||||||

| TOOLS HOLDER SIZE | ||||||||

| 18 | TOOLS HOLDER STANDARD | MSA403 BT40 | ||||||

| 19 | RIVET STANDARD | MSA403 P40T-1 | ||||||

| FEED | ||||||||

| 20 | X/Y FEED MOTOR MODEL | βiSC 22/2000 | ||||||

| 21 | X/Y FEED MOTOR MAX.SPEED | r/min | 2000 | |||||

| 22 | X/Y FEED MOTOR RATED POWER | kw | 2.5 | |||||

| 23 | X/Y FEED MOTOR RATED OUTPUT TORQUE | Nm | 20 | |||||

| 24 | Z AXIS FEED MOTOR MODEL | βiSC 22B/2000 | ||||||

| 25 | Z AXIS FEED MOTOR MAX SPEED | r/min | 2000 | |||||

| 26 | Z FEED MOTOR RATED POWER | kw | 2.5 | |||||

| 27 | Z FEED MOTOR RATED OUTPUT TORQUE | Nm | 20 | |||||

| 28 | X/Y FEED RATE | m/min | 15 | |||||

| 29 | Z FEED RATE | m/min | 12 | |||||

| 30 | CUTTING FEED SPEED | mm/min | 10000 | |||||

| TOOL MAGAZINE | ||||||||

| 31 | TOOLS MAGAZINE MODEL | MANIPULATOR | ||||||

| 32 | CAPACITY | pcs | 24 | |||||

| 33 | FULL TOOLS MAX TOOL DIAMETER | mm | Ф78 | |||||

| 34 | NEIGHBOR EMPTY TOOL DIAMETER | mm | Ф100 | |||||

| 35 | MAX.TOOLS ALLOWABLE WEIGHT | kg | 8 | |||||

| 36 | MAX.TOOLS ALLOWABLE LENGTH | mm | 300 | |||||

| 37 | TOOL CHANGE TIME | s | 3.5 | |||||

| 38 | TOOL CHANGE WAY | FORWARD/REVERSAL | ||||||

| POWER SOURCE | ||||||||

| 39 | MACHINE ELECTRIC CAPACITY | KVA | 20 | |||||

| 40 | COOLING PUMP FLOW RATE | L/min | 40 | |||||

| 41 | MACHINE COMPRESSED AIR | kg | 6~8 | |||||

| 42 | POWER REQUIREMENT | 380V±10% 50Hz | ||||||

| ENVIRONMENTAL REQUIREMENT | ||||||||

| 43 | ENVIRONMENTAL TEMPERATURE REQUIREMENT | 0ºC~40ºC | ||||||

| 44 | RELATIVE HUMIDITY | 20%~80% | ||||||

| MACHINE SIZE | ||||||||

| 45 | MACHINE DIMENSION | mm | 3300*2700*3000 | |||||

| 46 | MACHINE WEIGHT | kg | 8500 | |||||

| 47 | MACHINE SHIELD | FULL PROTECT | ||||||

| ACCURACY | ||||||||

| 48 | X/Y/Z POSITION ACCURACY | mm | ±0.012 | |||||

| 49 | X/Y/Z RE-POSITION ACCURACY | mm | ±0.008 | |||||

About SINO

Established in 1928, Sino Machinery Co., Ltd, is a factory which specializes in developing, manufacturing and selling of various types of conventional

milling machines,CNC milling machines and machining centers. Currently we have

more than 500 employees.Among them, there are 180 Professional technicians, 30 qualityinspector. We introduced advanced processing equipment and talented

personnel, 95% of machine functional parts are applied with famous Taiwan brand and nicetesting equipment secure the machine's good stability and excellent performance.

Thus, We sino machine are enjoying good reputation home and abroad.

Our Services

What we can do for you?

1.Reply your inquiry in 24 working hours.(our normal working time:6:00~22:00)

2.Experienced staffs answer all your questions in time.

3.Customized design is available.

4.Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

5.Special discount and protection of sales are provided to our distributor.

6.Professional factory: We are manufacturer, specializing in producing all kinds of CNC MACHINING CENTER.

7. As an honest seller, we always use superior raw material, advanced processing/testing machines,

skilled technicians to ensure our products to be finished in high quality and stable feature.

If the above model is not suitable for your workpiece, please tell us your need and then we can

send you the most satisfying drawing.

Our Services

What we can do for you?

1.Reply your inquiry in 24 working hours.(our normal working time:6:00~22:00)

2.Experienced staffs answer all your questions in time.

3.Customized design is available.

4.Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

5.Special discount and protection of sales are provided to our distributor.

6.Professional factory: We are manufacturer, specializing in producing all kinds of CNC MACHINING CENTER.

7. As an honest seller, we always use superior raw material, advanced processing/testing machines,

skilled technicians to ensure our products to be finished in high quality and stable feature.

If the above model is not suitable for your workpiece, please tell us your need and then we can

send you the most satisfying drawing.

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.